Have you ever seen an alloy wheel that’s almost impossibly shiny? If you’ve jealously wondered how your alloys can achieve the same look then read on: our diamond cutting service is all you need.

Have you ever seen an alloy wheel that’s almost impossibly shiny? If you’ve jealously wondered how your alloys can achieve the same look then read on: our diamond cutting service is all you need.

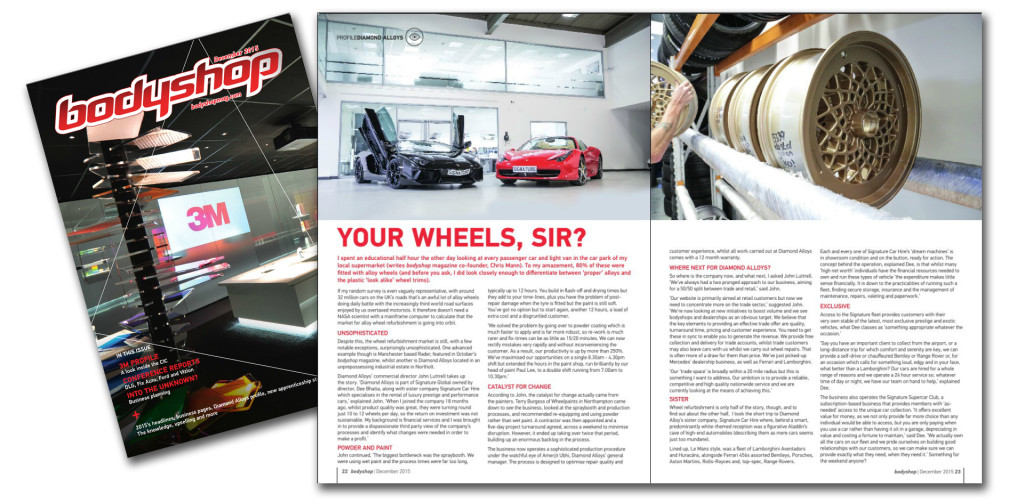

Diamond cutting is a very simple process to understand, but one that takes years for technicians to perfect. At the heart of the process is the act of putting a painted wheel on a lathe and machining off a minuscule part to leave a shiny finish. The only way to achieve this is by using a diamond drill, which is hard and sharp enough to achieve such a precise finish. To put it simply, without the diamonds the finish cannot be achieved.

Although the cutting part of the process is complex, the true finish can only be achieved by painstakingly following a series of steps both before and afterwards.

At Diamond Alloys we start by removing the wheel and aqua blasting it, something which removes all the layers of paint to be replaced along with any corrosion and detrimental brake dust. Once this is done our technicians examine the wheel to check for any damage that needs to be removed, and perform and repairs or further cleaning processes necessary. This is just one of the many times throughout the process that the wheel is examined in detail – by the end we know the wheel better than you do!

From here the wheel is painted, diamond cut and then covered in a state of the art scratch proof laquer. Because we aquablasted at the start, the layers of paint and laquer stick perfectly to the wheel, giving you a perfectly smooth finish. The wheel is then baked in an oven to set the lacquer before, you guessed it, more inspections and a final refit.

From here the wheel is painted, diamond cut and then covered in a state of the art scratch proof laquer. Because we aquablasted at the start, the layers of paint and laquer stick perfectly to the wheel, giving you a perfectly smooth finish. The wheel is then baked in an oven to set the lacquer before, you guessed it, more inspections and a final refit.

We believe that diamond cutting offers a truly premium finish, and as it can be done in 48 hours there’s really no excuse not to upgrade your look this summer! Prices start from £55, please call us on 0845 370 8881 for details.

Follow

Follow Britain’s bad roads have struck again, this time on a Range Rover. This car sustained kerb damage to its wheels that not only caused unsightly marks, but also put them at risk from corrosion and further damage.

Britain’s bad roads have struck again, this time on a Range Rover. This car sustained kerb damage to its wheels that not only caused unsightly marks, but also put them at risk from corrosion and further damage. On these wheels we used our

On these wheels we used our  Diamond cutting uses a high-strength precision tool that allows us to make smaller and more frequent cuts than any other method – ensuring the cleanest repair and the highest quality finish. After the wheel is repaired, we coat it with a scratch proof lacquer and bake it in our alloy oven.

Diamond cutting uses a high-strength precision tool that allows us to make smaller and more frequent cuts than any other method – ensuring the cleanest repair and the highest quality finish. After the wheel is repaired, we coat it with a scratch proof lacquer and bake it in our alloy oven. Aren’t these wheels pretty? They’re from a VW Caddy, and in these photos you can see that our repair work has restored them to their

Aren’t these wheels pretty? They’re from a VW Caddy, and in these photos you can see that our repair work has restored them to their  Repairing is a simple and cost-effective alternative to replacing your alloys, and our team of experts can have you back on the road in as little as 48 hours. The repair process will depend on the damage and the type of alloys you have, but in general terms it involves stripping them back completely to ensure all the damage is removed, then repairing the damage with a process such as

Repairing is a simple and cost-effective alternative to replacing your alloys, and our team of experts can have you back on the road in as little as 48 hours. The repair process will depend on the damage and the type of alloys you have, but in general terms it involves stripping them back completely to ensure all the damage is removed, then repairing the damage with a process such as

If you’re still not sure about the benefits of chemical stripping, watch our short film to see the process in action. This should reassure you that it does no damage to your actual alloys, but does efficiently remove everything that’s coating them.

If you’re still not sure about the benefits of chemical stripping, watch our short film to see the process in action. This should reassure you that it does no damage to your actual alloys, but does efficiently remove everything that’s coating them.

only be carried out by our trained technicians who have been repairing alloys for decades.

only be carried out by our trained technicians who have been repairing alloys for decades.

Kerb damage is pretty much what it says on the tin: damage to your alloys caused by banging them against a kerb. This most commonly happens during a parking manoeuvre and occurs a lot more than you might think: a recent survey found that one in 10 people had hit the kerb while parking, and one in nine had hit the kerb while driving. Interestingly, men and women are equally likely to do this, despite the driving stereotypes!

Kerb damage is pretty much what it says on the tin: damage to your alloys caused by banging them against a kerb. This most commonly happens during a parking manoeuvre and occurs a lot more than you might think: a recent survey found that one in 10 people had hit the kerb while parking, and one in nine had hit the kerb while driving. Interestingly, men and women are equally likely to do this, despite the driving stereotypes!