Ideally, not at the side of the road when something has gone wrong! Tyres are very easy to take for granted: we assume that they’ll always be supporting us, often without realising that they only have a limited lifespan.

Ideally, not at the side of the road when something has gone wrong! Tyres are very easy to take for granted: we assume that they’ll always be supporting us, often without realising that they only have a limited lifespan.

Looking after your tyres is a good way to ensure you minimise your chance of a breakdown, and it also saves you money! Remember that you’re only likely to get around 20,000 miles out of front tyres on a front-wheel-drive car, so changing your tyres is something that is necessary more often than you’d expect. In this blog we list signs as to when you should change your tyres, as well as handy tips to make them last longer.

When to change your tyres

When they’re old

When they’re old

If your car’s tyres are around 4-5 years old, then you need to start inspecting them at least once per year. In particular, check the tyres’ sidewalls for signs of cracking. If there is cracking, change them immediately. Tyres will degrade due to heat, sunlight, rain and other weather factors, as well as how and where you drive, so if you feel your tyres are too old it’s always safest to get them changed. Importantly, this also applies to if you feel they look old – it’s best to act on instinct and be safe rather than sorry.

When they’re breaking the legal limit for tread depth

There is a legal limit of 1.6mm for tyre tread depth – meaning that any tyres with a tread of less than 1.6mm are breaking the law. Check your tyres and replace them if they’re getting close to this limit – not only will it keep you legal but it will also keep you safe, particularly on wet roads.

When it’s damaged

When it’s damaged

If you hit a pothole, or bump the kerb, or run over something sharp, then it’s time to get your tyre checked. This is best done by a professional, who can tell you authoritatively whether or not you need to get the tyre replaced. Don’t ever drive on damaged tyres because the damage may be far worse than meets the eye – it’s important to get a thorough internal and external examination before you hit the road again.

If there are patches of wear

If you have small patches of abnormal wear, regardless of where they are on the tyre, they might indicate a mechanical problem, or an error in tyre pressure. If you spot these patches see a tyre specialist immediately, to ensure you stay safe on the road.

If they’re the wrong tyres

If tyres aren’t suited to your vehicle, then they’re likely to wear out while also reducing the handling ability of your car. You might also have soft compound tyres, which wear out more quickly, when you’d be better off investing in hard compound tyres.

So what can you do to decrease wear to your tyres?

So what can you do to decrease wear to your tyres?

These aren’t foolproof, but by changing your habits you could save money by making your tyres last that little bit longer.

Drive calmer

Aggressive cornering and braking increases wear – chill out and give your tyres a break!

Drive slower

It might not be what you want to hear, but driving slowly helps your tyres, as slow speeds = lower temperatures and less wear.

Take less stuff

Do you need everything in your car? Excess load increases wear, so remove superfluous items (no, not your mother in law) where possible.

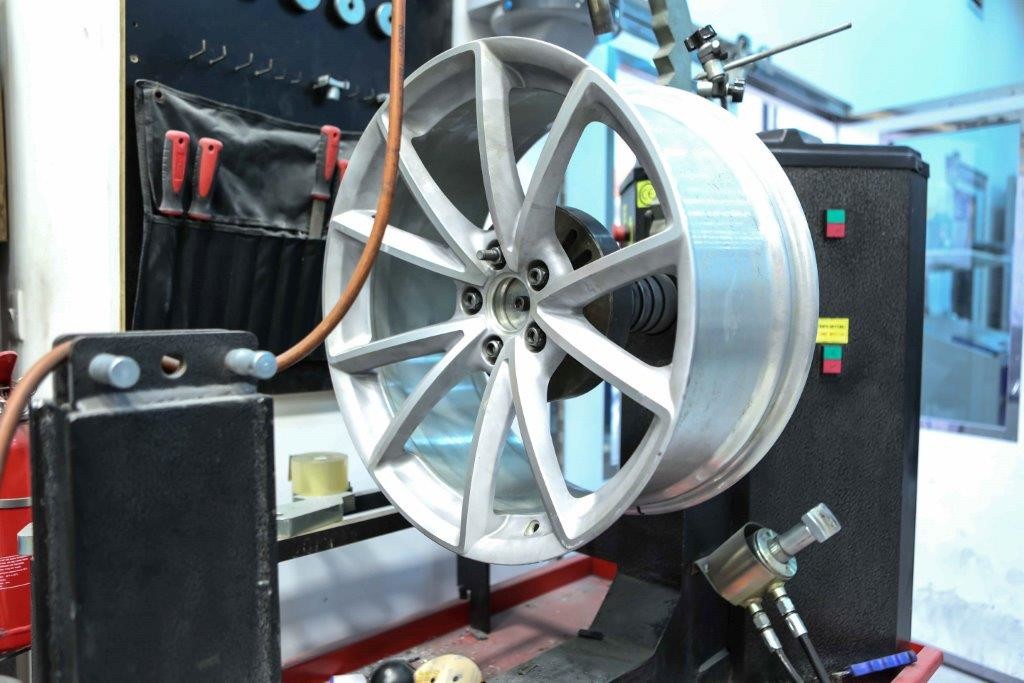

Ensure your tyres are aligned

Faulty wheel alignment causes wear, so get this checked regularly if you can.

Keep up the pressure

Ensure your tyres are kept at the correct pressure, as deviation either way will increase wear.

Check your tyres!

If you check your tyres on a regular basis, particularly before a long trip, you’ll be able to troubleshoot issues before they snowball and you end up stranded by the side of that road.

It’s amazing how much difference a new coat of paint can make. It might be more obvious on a house, or in your office, where you pay attention to the decor every day, but it’s even true on your alloys – and whereas you may have become accustomed to overlooking them every time you get into your car, you’ll now stop to admire them before and after any journey!

It’s amazing how much difference a new coat of paint can make. It might be more obvious on a house, or in your office, where you pay attention to the decor every day, but it’s even true on your alloys – and whereas you may have become accustomed to overlooking them every time you get into your car, you’ll now stop to admire them before and after any journey!

Follow

Follow Aren’t these wheels pretty? They’re from a VW Caddy, and in these photos you can see that our repair work has restored them to their

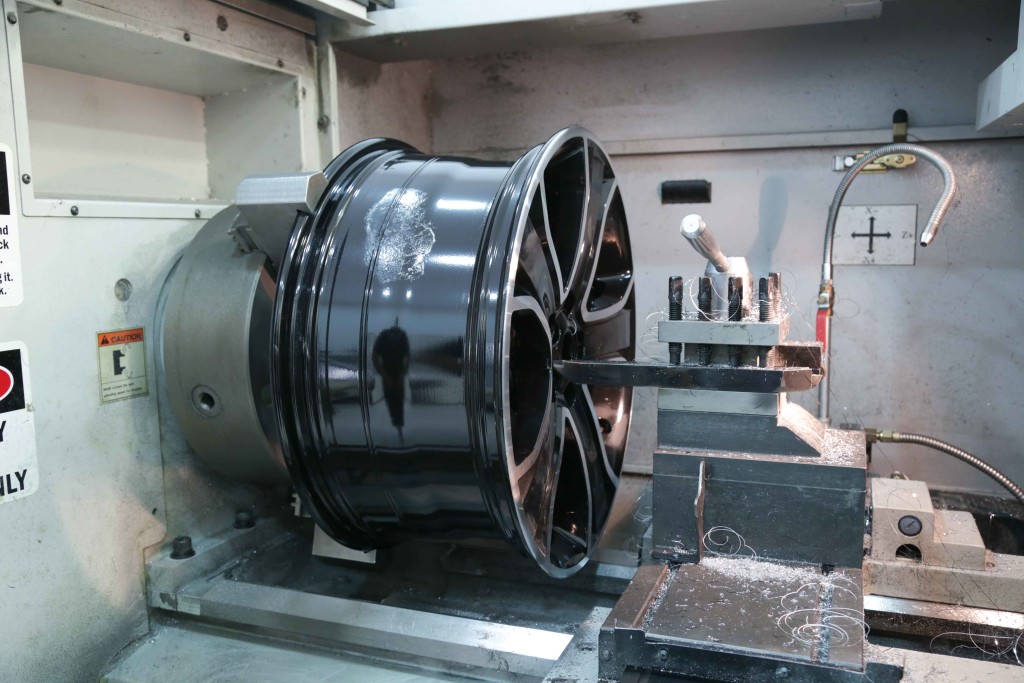

Aren’t these wheels pretty? They’re from a VW Caddy, and in these photos you can see that our repair work has restored them to their  Repairing is a simple and cost-effective alternative to replacing your alloys, and our team of experts can have you back on the road in as little as 48 hours. The repair process will depend on the damage and the type of alloys you have, but in general terms it involves stripping them back completely to ensure all the damage is removed, then repairing the damage with a process such as

Repairing is a simple and cost-effective alternative to replacing your alloys, and our team of experts can have you back on the road in as little as 48 hours. The repair process will depend on the damage and the type of alloys you have, but in general terms it involves stripping them back completely to ensure all the damage is removed, then repairing the damage with a process such as

If you’re still not sure about the benefits of chemical stripping, watch our short film to see the process in action. This should reassure you that it does no damage to your actual alloys, but does efficiently remove everything that’s coating them.

If you’re still not sure about the benefits of chemical stripping, watch our short film to see the process in action. This should reassure you that it does no damage to your actual alloys, but does efficiently remove everything that’s coating them.

only be carried out by our trained technicians who have been repairing alloys for decades.

only be carried out by our trained technicians who have been repairing alloys for decades.